UV printing is an interesting beast!

In my day to day work within the print industry, I will often hear the phrase “…it is… what it is…”. And although this statement is thrown around in many instances and in many scenarios… I sometime believe it is true for UV print. I mean, really…it can’t be anything else right?

But within that very thought around the process of UV print, what it is… and what it is capable of are two very different things!

In it’s rawest for, UV printing is… well… just one method of… well… throwing ink on something!

But due to the very nature of the UV printing process… hidden potential lies in waiting!

You see, when printing using the IV process, the curing that occurs from the controlled UV light means that the printed layer of ink… can be gradually built up! Then, depending on the control and precision of the machine and technology… layers can be formed and played with to gain some very exciting results!

The build up of layers and textures is known as “relief printing”.

One such example was the recent printing project I ran as a way of customising the “wrap bands” for the full set editions of the “Real Space” series.

To begin with… like all print projects, the artwork set up was key.

And for this project, the vision was to print a “white” version of the Wez’s World logo onto brown/tan stock.

The artwork was set up to trigger a “white” channel (fancy term for printing white).

Once the artwork was set up, next comes the “prepress”… meaning the assigning of settings and ensuring the desired result is achieved.

As you can see in the following image, the settings are all honed in to suit the combination of artwork, machine potential and desired outcomes. From resolution through to the “density” of the white per layer can be honed in with great precision…

Then, the “step and repeat” process is activated and set (this lays out a number of copies in a precise format within a single print

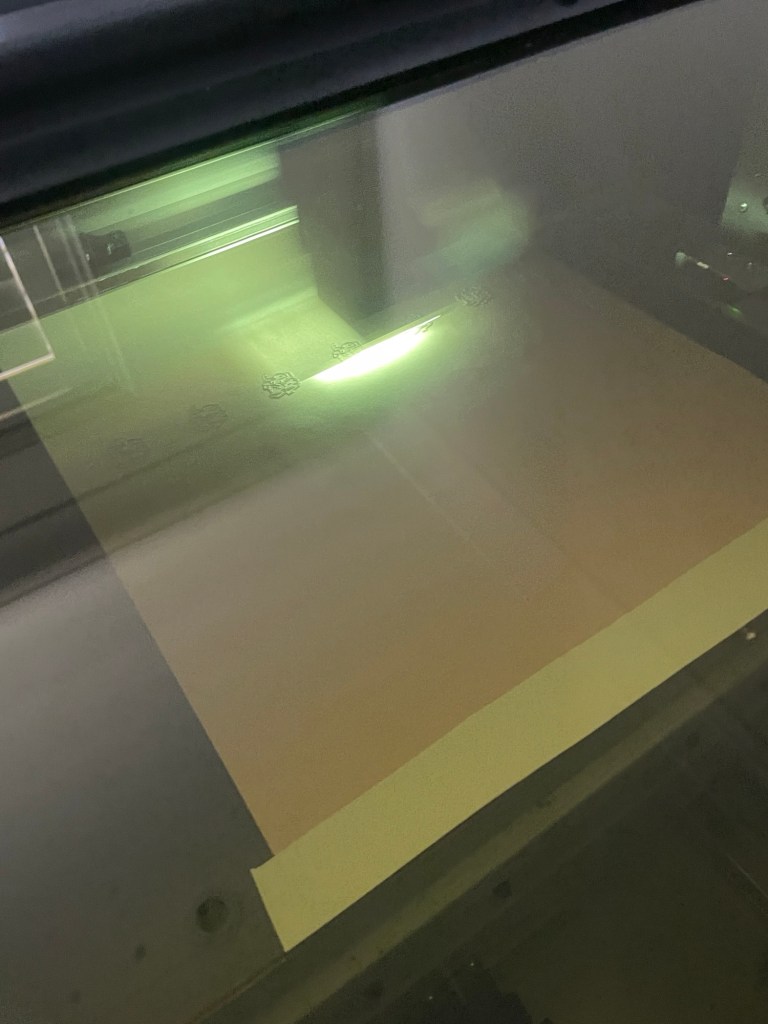

And once all things are setup, assigned and ready to go… its time to print.

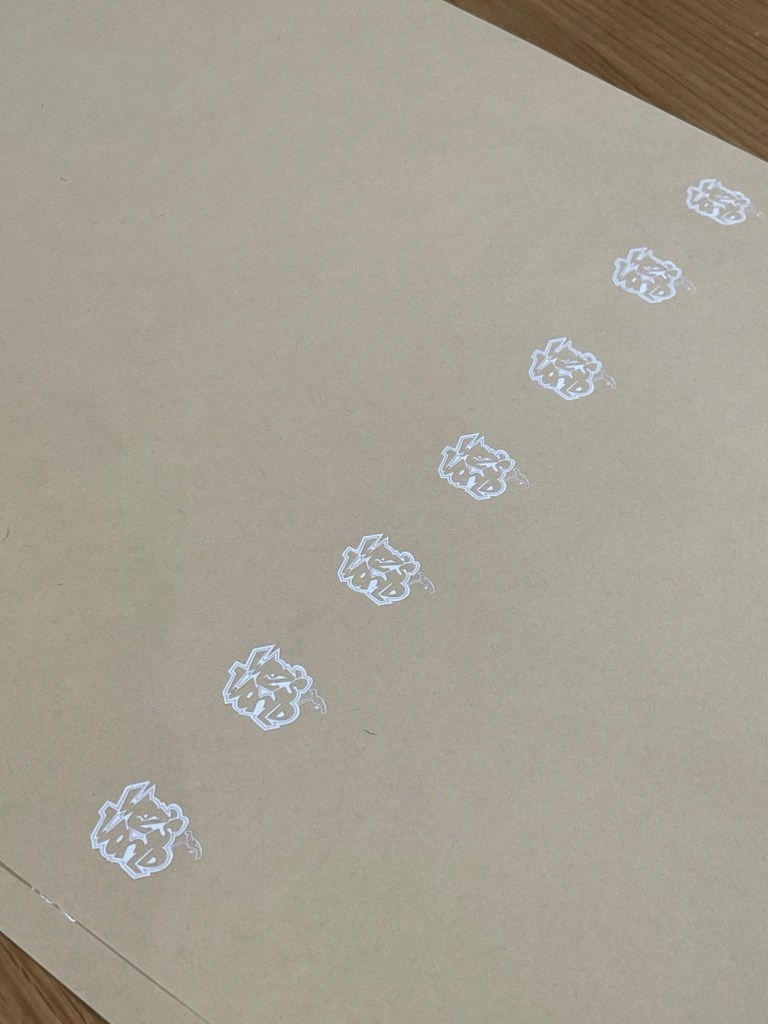

And its not long before the results speak for themselves…

With sheets printed and ready to go… its time for cutting…

Then once cut, the bands were wrapped round the sets of 5boxes and are ready for the world!

As you can see, relief printing is a technique that can deliver amazing results when used in the right way! This example is by no means the limit in height or texture… Who knows where the potential may be for using relief techniques on Lego bricks…

The Real Space series will be available online soon, but are already available in person! If you would like a box or perhaps the complete set, be sure to come along to one of the Sydney Brick Markets before they sell out!

Wez’s World is NOT affiliated with nor does not claim to be trading as part of LEGO Group.

LEGO is a registered trademark of the LEGO Group